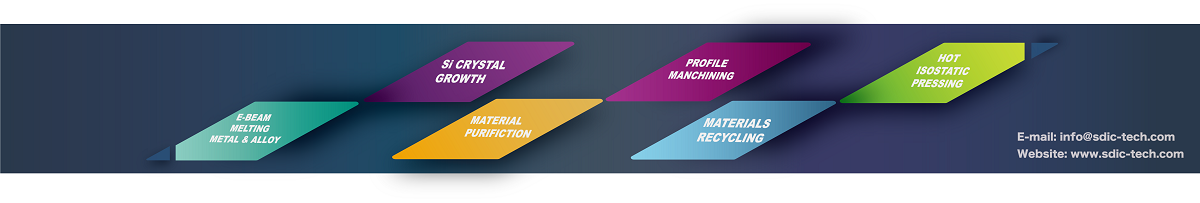

SDIC Main Process and Service

From an exellent sourcing of high-quality materials through the mian process and sevice of SDIC: Crystal Growth, Material Purification, Hot Isotatic Press, Vacuum E-Beam Melting, Profile Machining.

SDIC offers a lot of trustful items for different applications of the inquiry of industry, there are

Si Wafer, Si profiled Parts, Sputtering Targets, Evaporation Material, High Purity Material and the Profiled Metals and Alloys available.

Crystal growth is the process where a pre-existing crystal becomes larger as more molecules or ions add in their positions

in the crystal lattice or a solution is developed into a crystal and further growth is processed.

These growing methods are available in our service.

-

Czochalski method(CZ)

-

Floatzone puller (FZ)

-

Vertical Gradient Freeze(VGF)

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals

and increase the density of many ceramic materials. This improves the material's mechanical properties

and workability.

SDIC offers toll HIP for research and production specializing in high temperature and fast turnaround.

A wide variety of temperature and pressure products including HIP, CIP, WIP, SinterHIPs, Vacuum Furnaces

are also availble in our servic

SDIC EBeaMachines utilize a high power electron beam that generates the energy needed

for high melting capacity and high productivity.

The electron beam is managed

by electromagnetic coils providing extremely fast and accurate beam control.

Features:

Volume:250 mm diameter x 430 mm height

Temperatures exceeding 1000°C

-

Grinding Machine

-

Square Machine

-

Cutting Machine

-

Gluing Machine

-

Wire extrution Machine

Available by shape:

Wafer, Ingot, Planar, Rod, Wire, Disk